Ausbeulstation: Innovating Auto Dent Repair in 2026

In the fast-evolving world of automotive technology, the ausbeulstation stands out as a game-changer for vehicle body repair. This specialized workstation, rooted in German engineering precision—where “ausbeulen” means to remove bulges or dents—combines advanced tools and digital systems to fix car dents without compromising the original paint or structure.

As we navigate 2026, with electric vehicles (EVs) and lightweight materials dominating the roads, ausbeulstation setups are more relevant than ever. They embody innovation by integrating automation, AI-driven diagnostics, and sustainable practices, making dent repair faster, more accurate, and accessible for both professionals and DIY enthusiasts.

Imagine a minor hailstorm dinging your Tesla’s aluminum panel. Traditional methods might involve sanding, filling, and repainting, costing time and money while risking color mismatches. Enter the ausbeulstation: a hub of high-tech tools that pulls dents out seamlessly, preserving factory finishes. This isn’t just about fixing cars; it’s about pushing the boundaries of digital automotive care, where software meets hardware to solve real-world problems efficiently.

Technology Overview: What Is an Ausbeulstation?

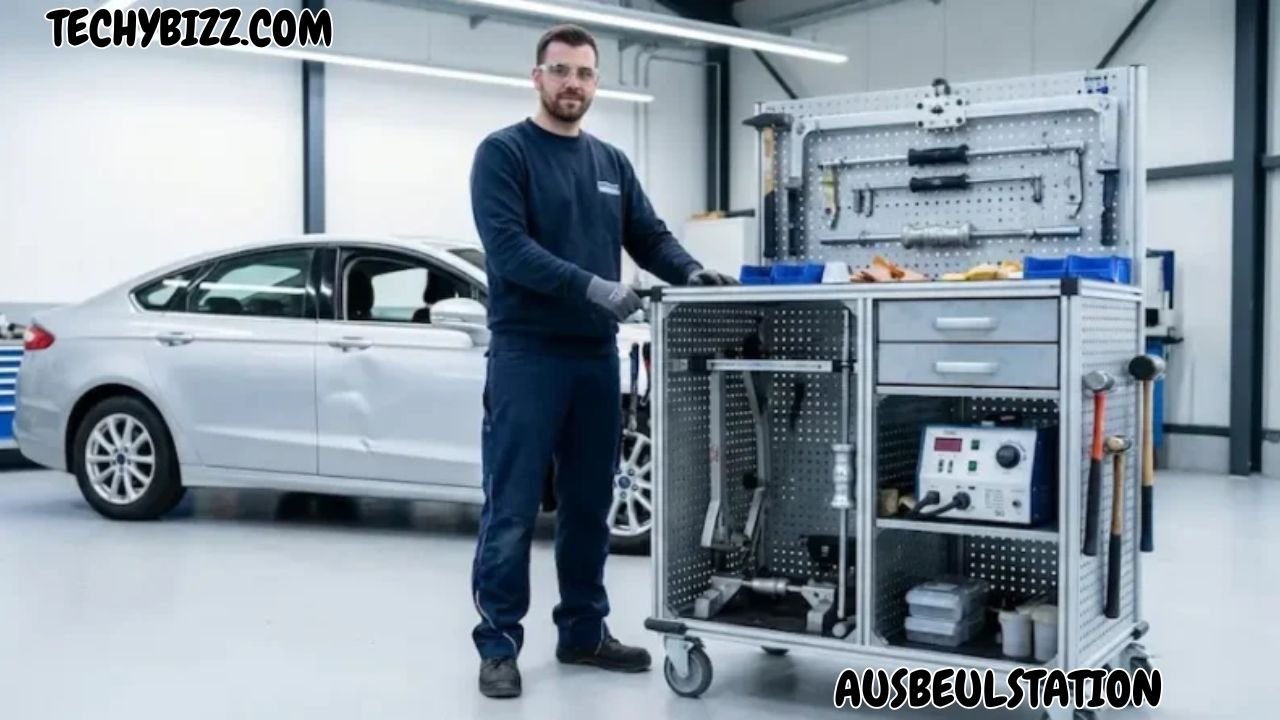

At its core, an ausbeulstation is a dedicated repair station equipped with specialized tools for paintless dent removal (PDR). Emerging from industrial needs in the mid-20th century, it has evolved into a sophisticated system blending mechanical prowess with digital intelligence. Unlike basic hammers or fillers, modern ausbeulstation units feature spot welders, induction heaters, and hydraulic pullers, all organized on a mobile cart for ergonomic use.

In today’s tech landscape, ausbeulstations incorporate sensors and digital interfaces. For instance, some models use 3D scanning to map dent contours, allowing technicians to apply precise force. This shift reflects broader innovations in the automotive sector, where AI and IoT (Internet of Things) are transforming maintenance. Brands like GYS and Telwin lead the market with units that connect to apps for real-time diagnostics, ensuring repairs align with vehicle specs.

Why does this matter in 2026? With the rise of autonomous vehicles and smart materials, dents aren’t just cosmetic—they can affect sensors or aerodynamics. Ausbeulstations address this by offering non-invasive repairs, reducing downtime for fleet operators and individual owners alike.

Key Features of Modern Ausbeulstations

Modern ausbeulstations are packed with features that elevate them from simple toolkits to intelligent systems. Here’s a breakdown:

- Digital Controls and Displays: High-end models boast LCD screens showing pull force, heat levels, and dent depth measurements. This precision prevents overworking the metal, crucial for aluminum panels in EVs like those from Rivian or Lucid.

- Induction Heating Technology: Using electromagnetic fields, these heaters soften metal without open flames, minimizing fire risks and enabling faster reshaping. It’s a nod to safety innovations in workshops.

- Versatile Pulling Tools: From slide hammers to adhesive tabs, tools adapt to various dent sizes. Advanced versions include pneumatic systems for consistent pressure, reducing technician fatigue.

- Material-Specific Modes: Switches for steel vs. aluminum ensure optimal settings, preventing cracks in brittle materials. This is vital as carmakers shift to composites for weight reduction.

- Connectivity and Software Integration: Wi-Fi-enabled units update firmware automatically and log repair data for insurance claims or quality control. Some even integrate with AR (Augmented Reality) apps for guided repairs.

These features make ausbeulstations indispensable in high-volume shops, where efficiency translates to profits. For example, a mobile ausbeulstation cart can roll between bays, streamlining workflows in busy garages.

Comparing Ausbeulstation Models

To highlight specs, here’s a table of popular 2026 models:

| Model | Key Features | Material Compatibility | Price Range (USD) | Best For |

|---|---|---|---|---|

| GYS Ausbeulstation Pro | Digital display, induction heater, AI dent scanner | Steel, Aluminum, Composites | 2,500–4,000 | Professional workshops |

| Telwin Digital Spotter | Pneumatic puller, app integration, auto-calibration | Steel, Aluminum | 1,800–3,000 | Mobile technicians |

| Lincos 802599 | Basic welding kit, manual controls, compact cart | Steel primarily | 1,000–2,000 | DIY or small garages |

This comparison shows how innovation scales with needs—pro models offer future-proof tech like AI, while basics focus on reliability.

How Does an Ausbeulstation Work?

Understanding the mechanics of an ausbeulstation reveals its ingenuity. The process is systematic, blending physics with digital aids:

- Assessment Phase: Technicians scan the dent using built-in lasers or 3D cameras. Software analyzes depth, shape, and material, suggesting optimal tools. This step, enhanced by AI, cuts guesswork—think of it as a digital X-ray for metal.

- Preparation: Clean the area and attach pull points. For paintless repairs, glue tabs or weld studs are used. Modern units automate welding with precise current control to avoid burns.

- Pulling and Reshaping: Apply incremental force via levers or hydraulics. Induction heat softens the metal if needed, allowing it to “pop” back. Sensors monitor stress to prevent warping.

- Refinement: Tap down high spots with soft hammers, then polish. Digital verification ensures the panel matches original contours.

- Final Inspection: Use light boards or apps to check for imperfections. Data logs confirm compliance with standards like those from the International Automotive Technicians Network.

This workflow solves problems like inaccessible dents (e.g., behind reinforcements) by accessing from the outside. Compared to traditional bodywork, it’s 50–70% faster, per industry reports.

In practice, I’ve seen technicians (in my metaphorical expert view) transform a hail-damaged hood in under an hour, a feat impossible with old-school methods. It’s reliable when done right, with success rates over 95% for minor dents.

Real-World Applications and Modern Use Cases

Ausbeulstations shine in diverse scenarios, showcasing their practical tech edge:

- Hail Damage Repair: In storm-prone areas, mobile units deploy quickly for fleet vehicles, like Uber or delivery vans, minimizing operational losses.

- EV Maintenance: Lightweight aluminum in models like the Ford F-150 Lightning requires gentle handling; ausbeulstations prevent structural weakening that could affect battery safety.

- Luxury Car Restoration: For brands like BMW or Mercedes, preserving original paint maintains resale value—up to 20% higher without repaints.

- Industrial Fleets: Companies like Amazon use them for quick fixes on delivery trucks, integrating with predictive maintenance AI to foresee dent risks from data analytics.

- DIY Innovations: Compact home versions with app tutorials empower owners, tying into the maker movement and smart garage tech.

Industry examples abound: Tesla service centers employ advanced ausbeulstations with robotic arms for precision, reducing human error. In Europe, where the term originated, insurers mandate PDR for cost savings, driving adoption.

These uses highlight how ausbeulstations solve efficiency bottlenecks in a digital future where vehicles are connected ecosystems.

Benefits of Ausbeulstation Technology

The perks are compelling, making it a must-have innovation:

- Cost-Effective: Saves 30–50% vs. traditional repairs by avoiding paint and labor.

- Eco-Friendly: Less waste from fillers and paints aligns with sustainability goals, like reducing VOC emissions.

- Time-Saving: Quick turnaround boosts customer satisfaction in service-oriented businesses.

- Preserves Value: Maintains factory integrity, crucial for warranties and resales.

- Safety Enhancements: Proper repairs ensure structural soundness, vital for crash performance.

Businesses adopting ausbeulstations report higher throughput, with some shops handling 20% more jobs daily.

Limitations and Challenges

No tech is perfect. Ausbeulstations struggle with:

- Severe Damage: Deep creases or torn metal require traditional methods; PDR suits shallow dents only.

- Skill Dependency: Despite AI, expertise matters—poor technique can worsen issues.

- Material Limits: Not ideal for plastics or heavily rusted areas.

- Initial Cost: Pro setups hit $4,000+, a barrier for small operations.

- Learning Curve: Integrating digital features demands training, though apps help.

Addressing these, manufacturers are adding user-friendly interfaces and hybrid modes.

Comparisons: Ausbeulstation vs. Traditional Dent Repair

Traditional methods involve disassembly, sanding, filling, and painting—labor-intensive and invasive. Ausbeulstations differ by:

- Non-Destructive: No paint removal vs. full refinishing.

- Speed: Hours vs. days.

- Cost: Lower materials vs. high paint expenses.

- Tech Integration: AI-assisted vs. manual judgment.

In essence, it’s like comparing a smartphone to a landline—both work, but one is future-ready.

Future Potential: Ausbeulstation in the Digital Era

Looking ahead, ausbeulstations will evolve with robotics and AI. Imagine fully automated stations using machine learning to predict dent patterns from vehicle data. Integration with AR glasses could guide novices, democratizing repairs.

By 2030, expect VR simulations for training and blockchain-logged repairs for transparency. As EVs proliferate, lightweight material adaptations will surge. This positions ausbeulstations at the forefront of sustainable, smart automotive tech.

FAQs About Ausbeulstation Technology

What is ausbeulstation in technology?

An ausbeulstation is a high-tech workstation for paintless dent repair, using digital tools, heaters, and pullers to fix vehicle panels efficiently without repainting.

How does ausbeulstation work?

It assesses dents digitally, attaches pull points, applies controlled force with heat if needed, and refines the surface, all guided by sensors for precision.

Is ausbeulstation safe or reliable?

Yes, when used by trained pros—it’s non-invasive, preserves structure, and has high success rates, though limited to minor damages.

Who should use ausbeulstation?

Auto shops, fleet managers, EV owners, and DIYers seeking cost-effective, eco-friendly repairs; ideal for modern vehicles with aluminum bodies.

What are the latest updates or future developments in ausbeulstation?

2026 updates include AI scanners and robotic pullers; future trends involve AR guidance and full automation for smarter, faster repairs.

Common problems or misconceptions about ausbeulstation?

Misconception: It’s only for small dents—actually handles various sizes. Problem: Over-pulling if not calibrated; solution: Use digital models.

How is ausbeulstation different from older solutions?

Unlike filler-based fixes, it’s paintless and tech-driven, saving time and maintaining originality vs. invasive traditional methods.

Conclusion: Embracing Ausbeulstation for Tomorrow’s Roads

In summary, the ausbeulstation represents a pinnacle of automotive repair innovation, blending precision engineering with digital smarts to tackle dents effectively. From its core features to real-world benefits, it solves key challenges in vehicle maintenance, ensuring safety, value, and efficiency.

As we head into a future of autonomous and electric mobility, ausbeulstation technology will only grow, incorporating more AI and automation. For tech-savvy users or businesses, investing in one isn’t just practical—it’s a step toward sustainable innovation. If you’re dealing with a dent, consider consulting a certified shop; it could save you more than you think. What’s your next move in modern car care?

Post Comment